Ensuring safety in the workplace is paramount for every organization. Safety inspection checklists are an effective tool to identify hazards and reduce the possibility of accidents. A safety inspection checklist template provides a structured approach to evaluating safety hazards at the workplace. The template is a great resource for facility managers, safety officers, and other safety professionals because it lists critical safety items that must be evaluated to reduce the risks of accidents.

Table of Contents

Using a safety inspection checklist template ensures that an organization complies with safety standards and regulations, protects employees from harm, and maintains a safe work environment. By incorporating a safety inspection checklist as part of routine safety procedures, organizations can promote a safety culture and minimize the chances of accidents.

Maintaining a safe work environment is a crucial responsibility for every employer. Employers must conduct regular safety inspections to ensure that their workplace is free from hazards and potential risks. A comprehensive safety inspection checklist should be developed to cover all key components that can threaten the employees’ well-being.

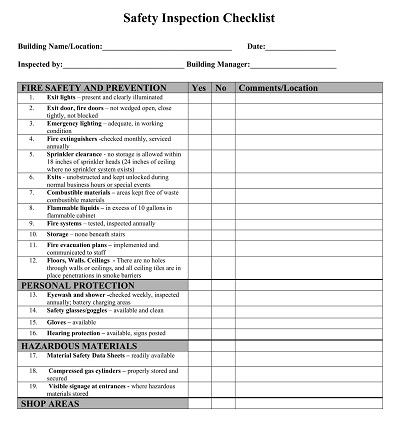

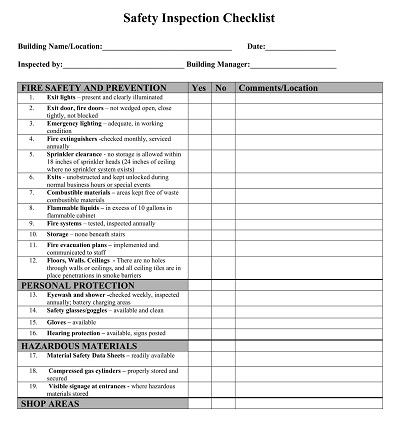

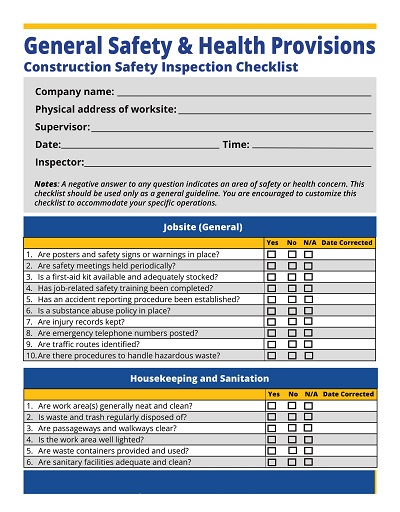

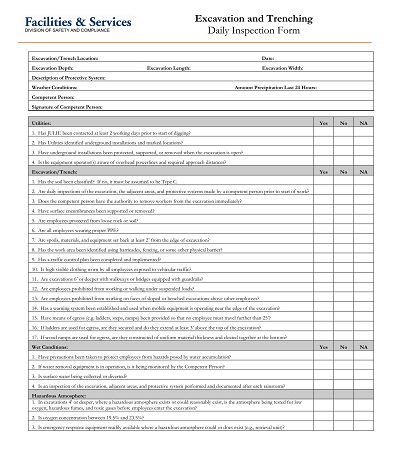

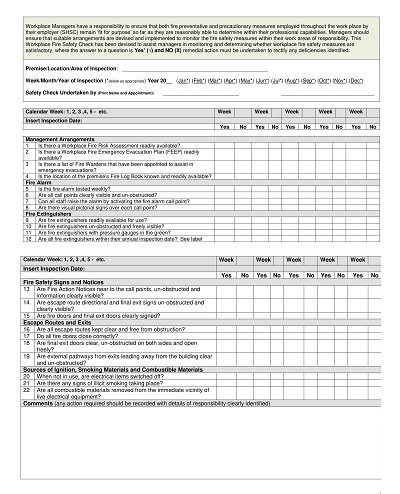

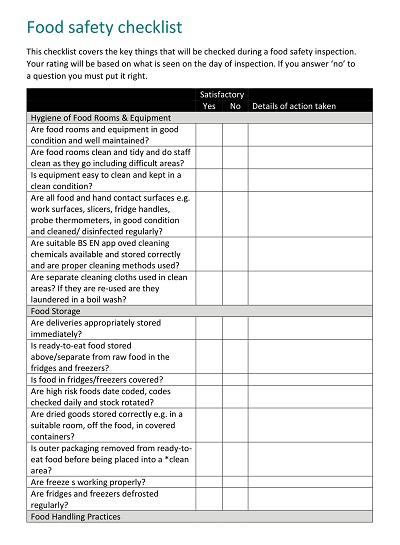

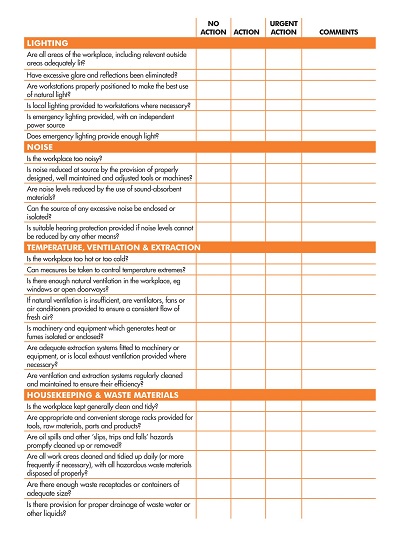

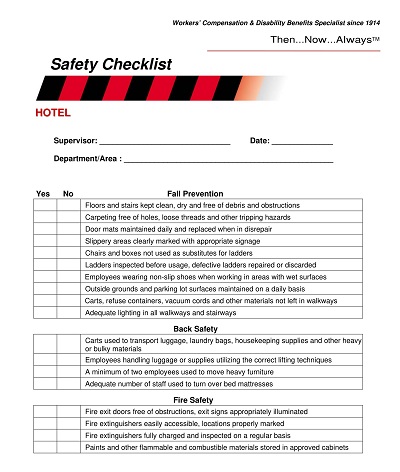

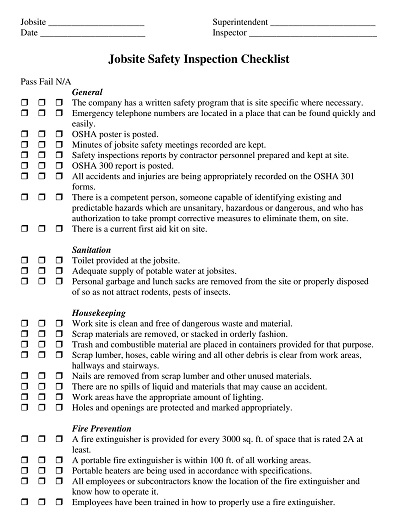

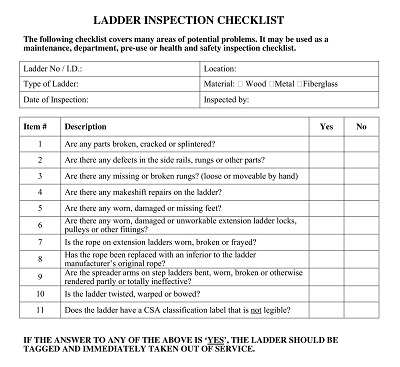

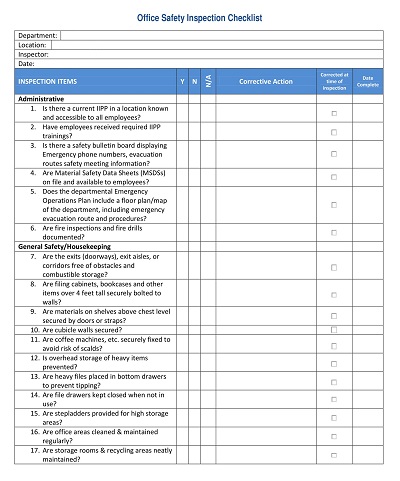

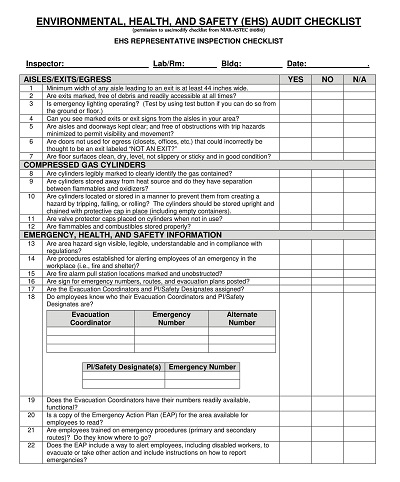

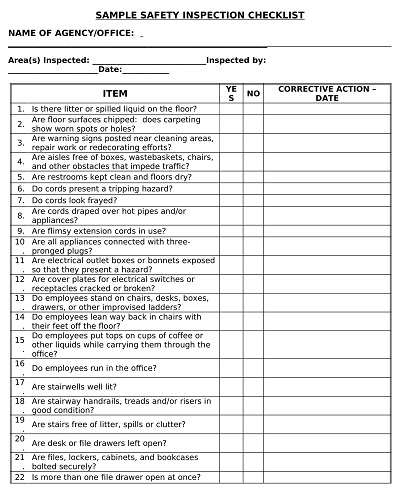

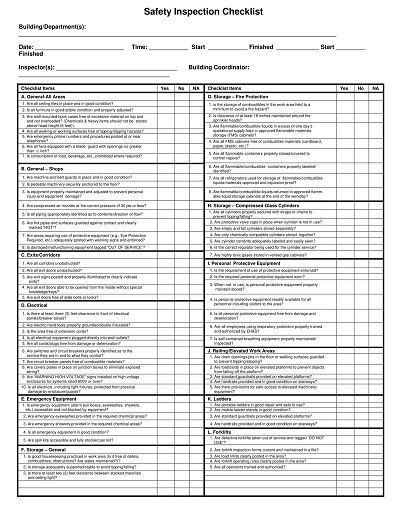

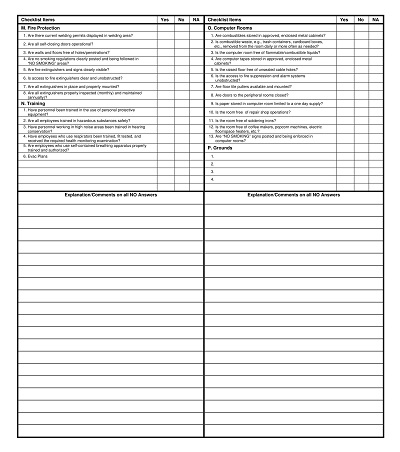

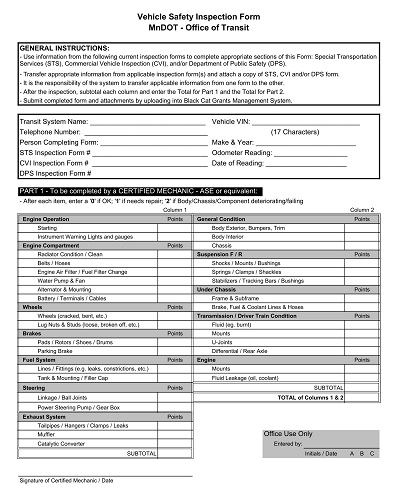

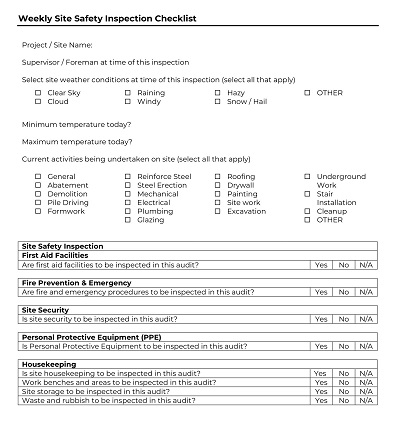

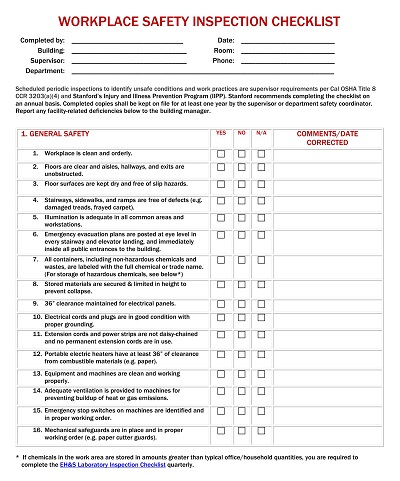

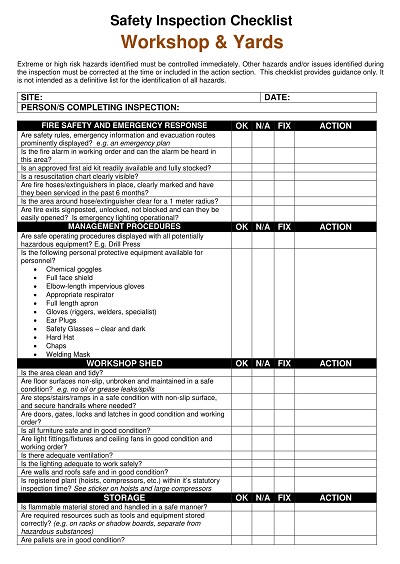

It should include inspection items like electrical systems, machinery and equipment, fire safety measures, ventilation systems, personal protective equipment, and emergency response systems. The safety checklist should be reviewed and updated regularly to ensure that it effectively addresses all the hazards that may arise in the workplace. By conducting regular safety inspections and using a comprehensive safety checklist, employers can prevent accidents and protect their employees’ health and safety in the workplace.

As a responsible and safety-conscious business owner or manager, ensuring that your workspace is safe and secure is crucial. One effective way to do that is by implementing a safety inspection checklist. This checklist can help you identify potential hazards and risks in your workplace that could put your employees or customers in danger.

You can take corrective actions and mitigate these risks by conducting regular inspections and completing the checklist. Not only can this help prevent accidents and injuries, but it can also improve productivity and reduce costs associated with workplace incidents. So why not take the steps necessary to create a safe workplace by implementing a safety inspection checklist?

Safety inspections are crucial in ensuring workplaces are free from hazards that might harm workers. Conducting regular safety inspections identifies potential issues that might have been overlooked and allows management to implement measures that will promote a safe working environment.

Documentation of safety inspections is equally important, as it provides a record of what was done during an inspection, including any hazards identified and the action taken to rectify them. Keeping records of safety inspections provides a clear picture of a workplace’s safety performance over time, which helps identify broader trends that must be addressed. For this reason, employers need to implement a comprehensive safety inspection program and ensure that all inspections are properly documented.

Safety is a top priority in any workplace, and regular inspections are essential in maintaining a safe environment for employees. However, creating a safety inspection checklist can be daunting, particularly for those new to the process. Fortunately, many resources are available to help guide you through creating an effective checklist.

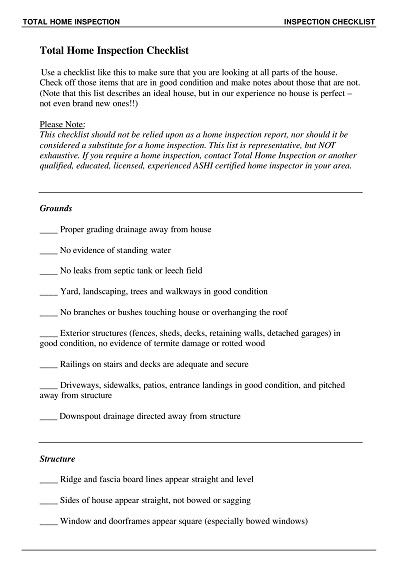

The first step in creating a safety inspection checklist is to identify potential hazards in the workplace. This can involve conducting a risk assessment, reviewing incident reports, and consulting with employees. Common hazards may include unsafe equipment, hazardous chemicals, poor lighting, or uneven flooring. Make sure to consider all potential areas of the workplace when identifying hazards, including workstations, break rooms, restrooms, and outdoor spaces.

Once you’ve identified potential hazards, the next step is to determine the criteria that will be used to inspect each area of the workplace. This may involve reviewing safety regulations and standards specific to your industry and consulting with experts in the field. Consider the specific needs of your workplace when developing inspection criteria, including the types of equipment used, the number of employees present, and the nature of the work being performed.

With your hazard identification and inspection criteria, you can begin creating your safety inspection checklist. It’s important to organize your checklist logically, starting with the most important or high-risk areas of the workplace. Include detailed descriptions of each item on the checklist and any required actions or follow-up steps. Be sure to include a space for the inspector to provide comments or notes and a section for corrective actions to be taken if any hazards are identified.

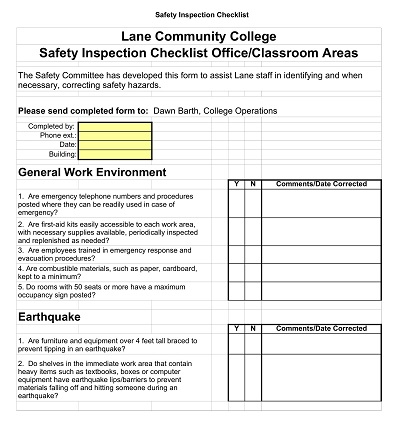

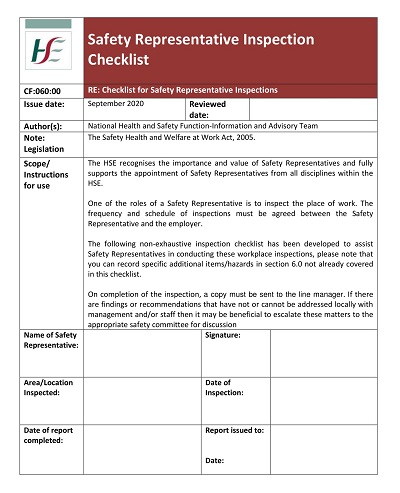

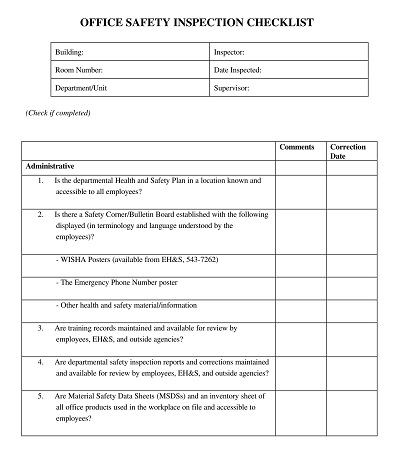

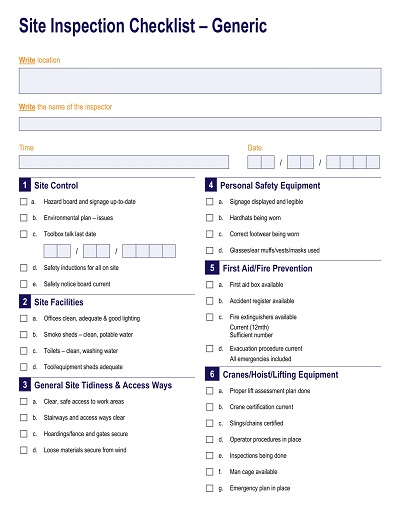

To make creating a safety inspection checklist even easier, we’ve provided a customizable template you can use as a starting point. This template includes all the necessary sections and items to conduct a thorough inspection of your workplace. Download the template and customize it to fit your specific needs.

A safety inspection checklist is the first step in maintaining a safe workplace. Schedule regular inspections and assign a trained inspector to perform them. After the inspections, follow up on any identified hazards and document all corrective actions taken. Additionally, please communicate with your employees about the inspection process and encourage their participation in ensuring a safe work environment.

How useful was this post?

Click on a star to rate it!

Average rating / 5. Vote count:

No votes so far! Be the first to rate this post.